With

almost 20 years of history, the University of Waterloo Formula SAE

Team is Canada's longest continuous running FSAE team. Here

is a look back of how it all began in May 1986, what the first car

was like, and how the team did at the 1987 FSAE Competition.

The Team members

Left to right -

Cathy Wilton, Al Ashton (kneeling, joined in the second year),

Chris Clements, Matt Crossley (in car), and Evan Jones. The Team

also had help from Andrew Strilbling and Greg Lamb, although they

did not travel to the event in Texas or participate for course

credit.

Introduction

In 1986, four

mechanical engineering students approached Dr. Allan Hale about

being their supervisor for their fourth year project to design,

build and race the first ever Waterloo entry in the Formula SAE

competition. Dr. Hale agreed and the project began with a trip to

the 1986 FSAE Competition held in Michigan. During that trip the

team saw a lot of pitfalls that they were determined to avoid -

cars being tested for the first time right at the competition,

poor preparation on various aspects of the judging scheme and some

design ideas that were suspect.

Four areas of

activity were highlighted by the team

-

getting

sponsorship money

-

building the

car well ahead of the competition to learn how to drive it

-

learning

techniques needed to effectively drive a race car

-

concentrating

on the presentation and documentation parts of the competition

The team also

decided to choose the simpler route whenever possible thats why

the car was made of mild steel and used a carburetor.

The Sponsors

-

Honda of

Canada provided a 500cc Interceptor engine at no cost

-

Yokahama Tires

provided racing slicks for the car

-

Schleuter Chev-Olds

painted the body Corvette yellow at no cost

-

Wolf Racing

built the exhaust system at cost

-

Bundy Canada

-

Raytheon

Canada

-

Fiberglas

Canada

-

Chevron

-

Waterloo Honda

-

University of

Waterloo, Department of Mechanical Engineering

supplied some cash, most of the raw materials, and performed the

final welding work at no cost

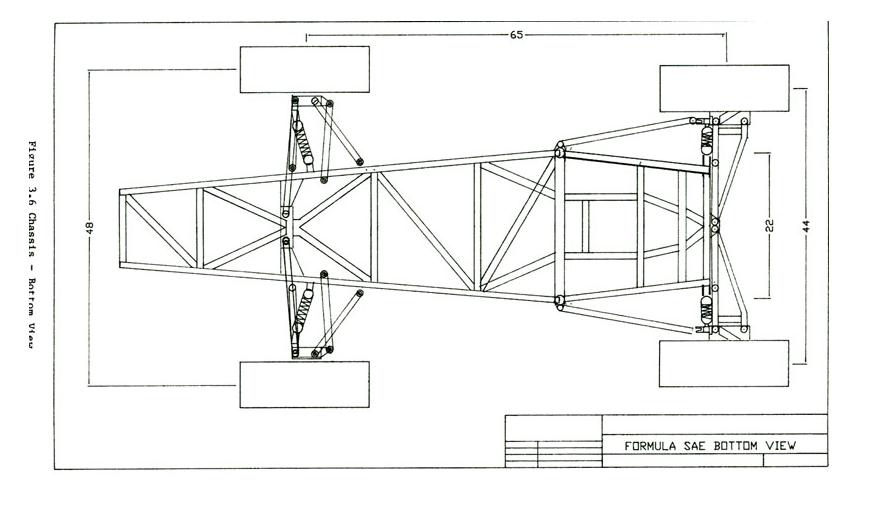

The Car

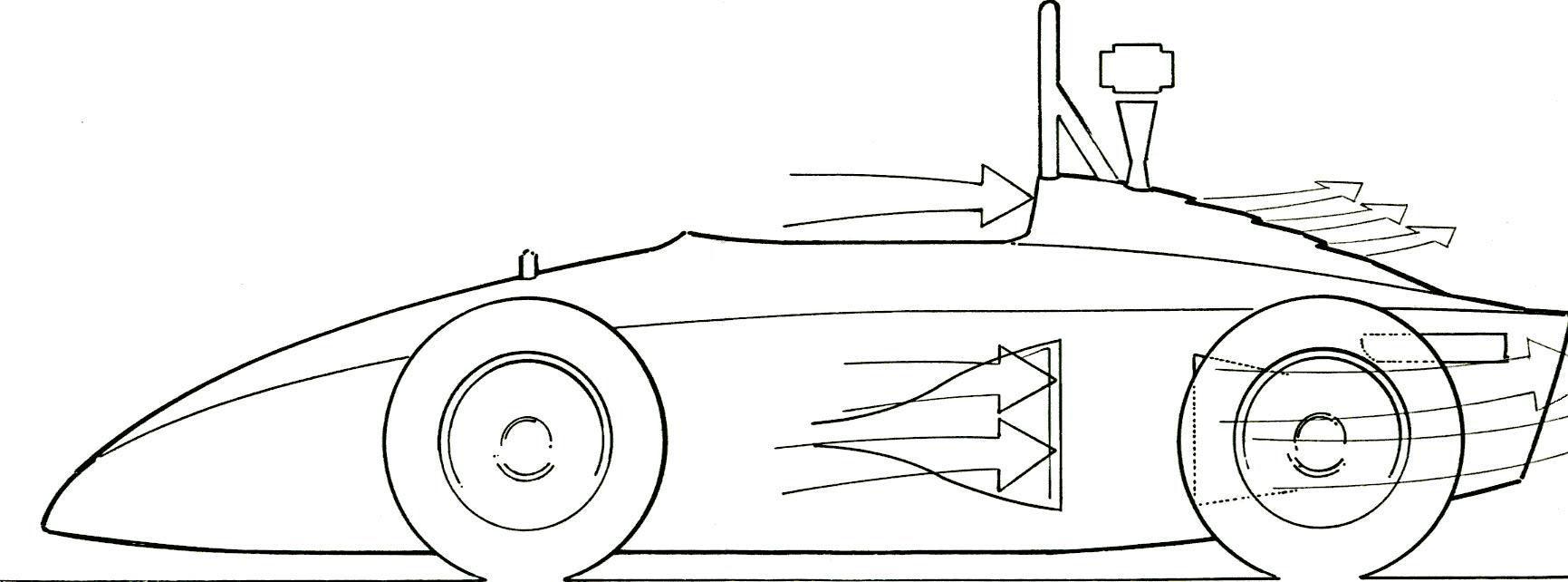

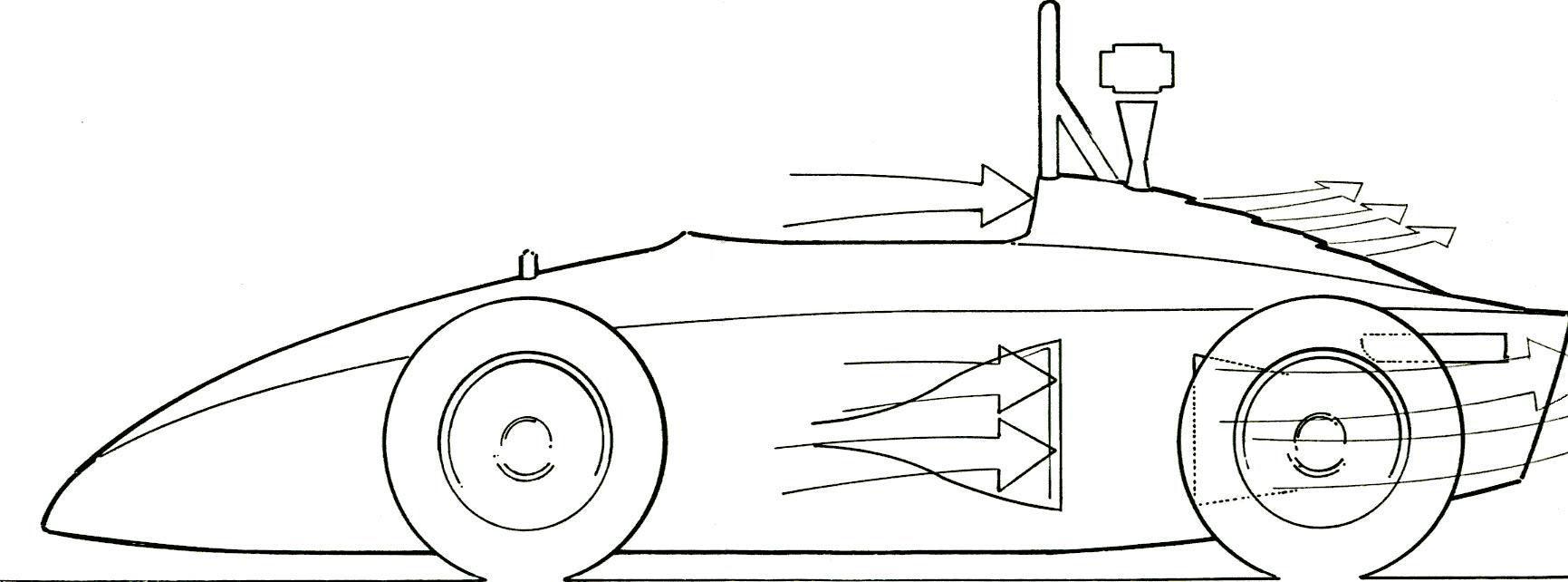

1987

Car Concept Drawing

Engine

A Honda V4 500cc

engine was chosen for its compact size and good power. Honda

Canada donated one engine. A second engine was taken from a

wrecked bike purchased from a local motorcycle shop. This also

yielded a wiring harness, cooling system and brake parts. It was

decided that a carburetor would be used to keeps things simple

compared to trying to climb the steep learning curve related to

fuel injection. The carburetor was mounted on a unique intake

track that allowed the fuel mixture to gradually expand on its way

down to the engine. The intake tract itself was laid up using

Kevlar over a wax mockup. Once heated, the wax evaporated and a

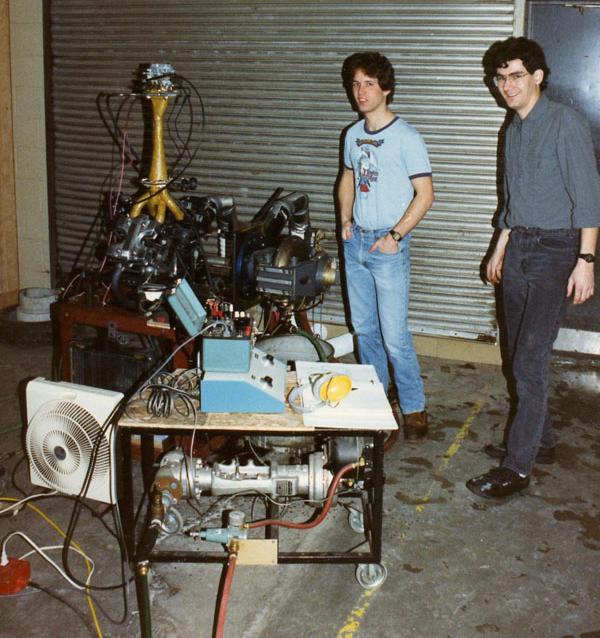

very smooth intake system was left. Matt Crossley borrowed a

water-driven dynamometer from General Motors (he had work terms at

GM) and this helped greatly in helping tune the engine to maximize

the horsepower.

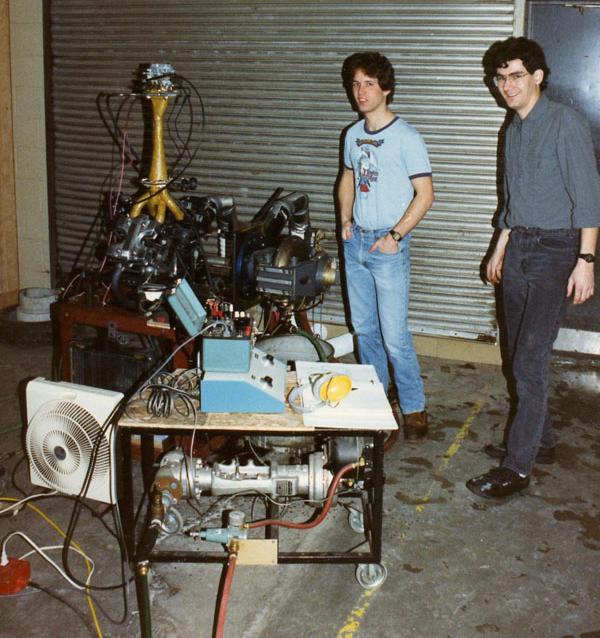

Dynamometer Test Set-up

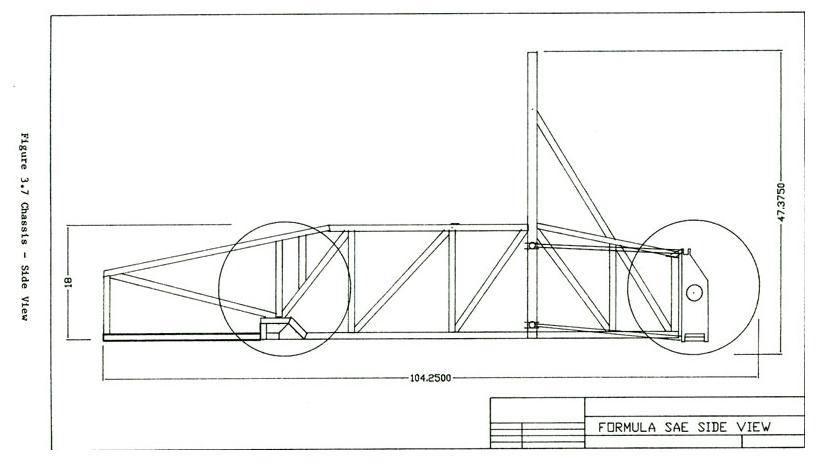

Chassis

Although heavier

than other materials, mild steel tubing was used throughout the

chassis because it allowed easy fabrication at very low cost.

Steel is also easier to repair as the team discovered after

bumping the front end into a parking lot curb. Chris Clements did

the bulk of the frame and suspension design and the car was

probably the safest car at the competition. The radiator was

mounted on the left side of the car, beside the cockpit. The

added expense and complexity of having two radiators was not

warranted. The team did all of the spot welding and the UW

Engineering Main Shop did all of the final welding of the frame.

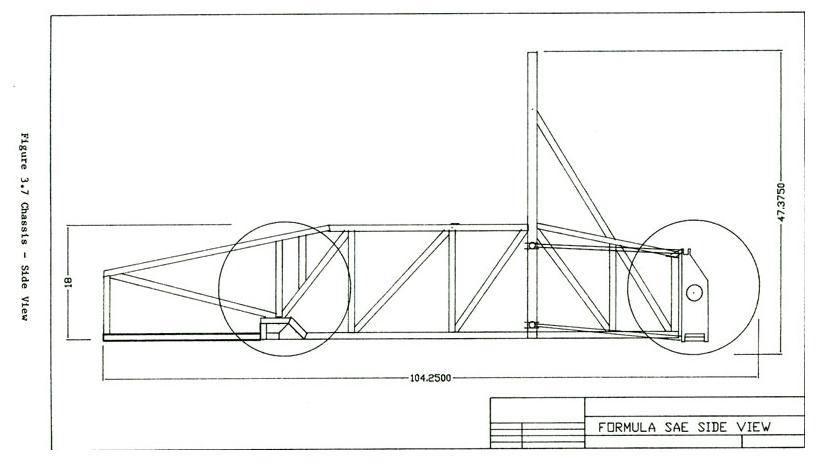

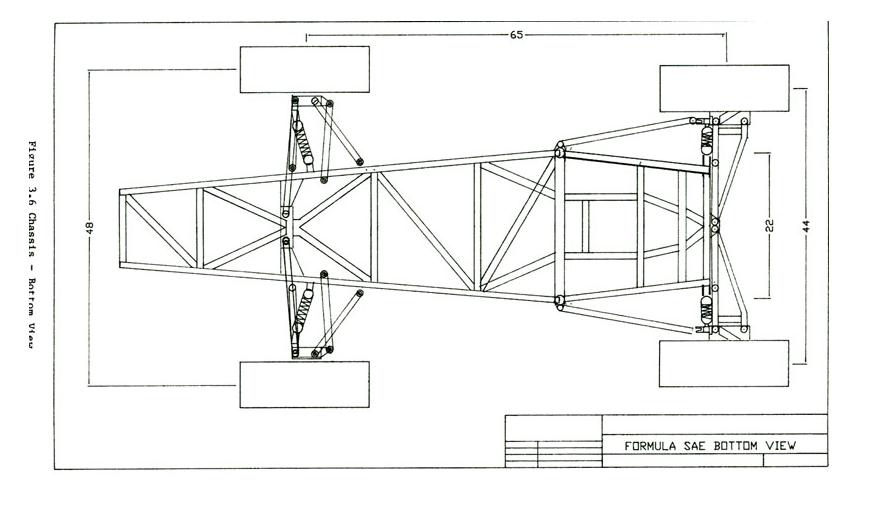

Side

View

Top

View

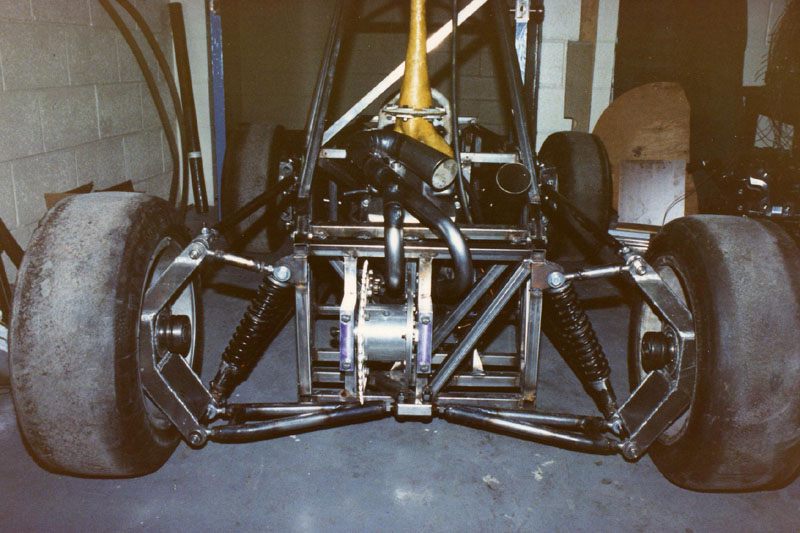

Suspension

The suspension

was independent on all four corners. The front suspension did not

use conventional double A or wishbone design, but a unique system

that used four linkage rods. This was very easy to fabricate and

allowed very fine tuning of the steering and cornering geometry.

The rear suspension had lower A arms, upper and leading linkages.

Used motorcycle shocks were mounted on all four corners. The

front wheels mounted on aluminum uprights and the rear used a

similar aluminum uprights.

Bare

Chassis - Ready for First Test Drive

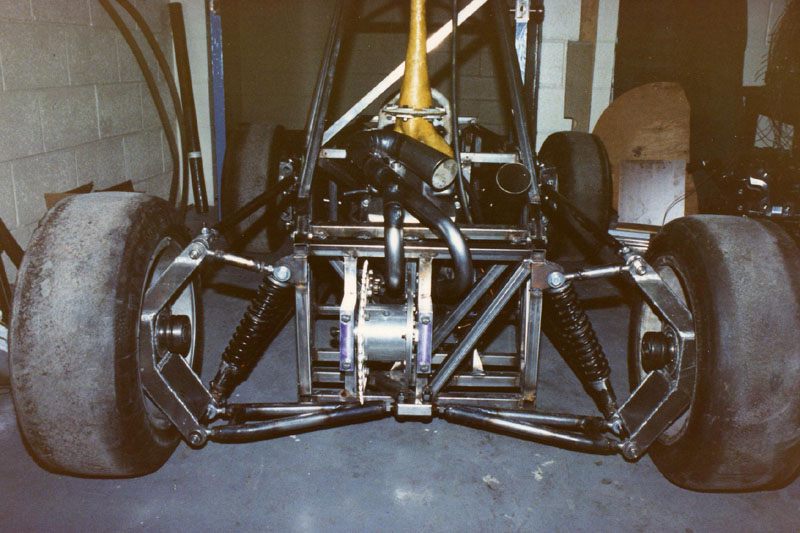

Power Train

The engine power

used a motorcycle chain to drive a unique differential setup. A

Morris Mini differential (found at an auto junk yard) was mounted

inside a specially designed housing. This housing was rotated by

the chain from the engine. The power was then fed through a

Morris Mini pair of CV joints to the rear wheels.

Rear

Suspension and Drive train

Steering and Brakes

A Morris Mini

rack and pinion steering unit was used for turning the front

wheels. The steering shaft was set up to allow the steering wheel

to be adjusted forward and backwards. This was to accommodate the

different sizes of the team members. (Cathy was about 57 and Al

was about 6 3) The rear brake disc was mounted to the

differential housing and the caliper mounted on the rear frame.

Body Work

The body work

was fabricated using a very unusual technique. First, blue

extruded polystyrene insulation (Styrofoam Blue) panels were

placed on the frame and around the radiator. Saws and files were

used to shape the body to the desired contours, including an NACA

scoop in front of the driver. Fiberglass cloth was then laid up

on top of the foam, followed by some minor spot puttying.

The Numbering

Since this was

the first year for

Waterloo

to compete in the event, the team was left to choose whatever

number it wanted for the car. ME462 was the course number for the

fourth year project and so 462 as chosen as the number for the

car.

Test

Driving the Car

The Competition

The 1987 FSAE

Competition was held at the University of

Texas

at Arlington and was spread out over three days.

May 28, 1987 First Day, Static events

Inspections of

the car and review of the documentation, the team placed 5th

overall.

May 29, 1987 Second Day

The

first event was the acceleration event and it was a DISASTER! The

team couldn't seem to get the car off the line without stalling.

After checking the car, a broken spring in the carb secondary was

found and so too were a rock in the primary jet and dirt in the

float bowl. Fixing these things still does not get the

acceleration back. The team earned 0 points for this event

because it did not beat the maximum allowed time. Later that day

the team realized the mistake - Canadian winter gasoline was used

for tuning the car before coming to

Texas!

The team subsequently purchased gas in Texas to run in the dynamic

events. This Texas gas had a lower evaporation rate because of

the higher temperatures and this lead to the acceleration

problems. The team re-jetted the carburetor as best as it could

and managed acceptable scores in the fuel economy (3rd

place) and maneuverability (6th place).

May 30, 1987 Third Day

The team stood

at

5th place overall despite its dismal result in the

acceleration. During warm ups for the endurance event, the

beautiful nose cone came sliding off the front of the car. Out

comes the engineers secret weapon duct tape and the car was

back in business. The car and the group of of drivers performed

beautifully. The team was 1 of only 3 teams that complete

both heats without any mechanical problems. This confirmed the

belief that keeping things simple and making sure that lots of car

testing before the competition would be beneficial. The Team

placed 3rd in the Endurance Event.

The Awards

The team

received the following awards:

-

Special

mention for innovative use of composite materials - the Kevlar

intake manifold had a lot of positive comments.

-

Winner of Team

Sportsmanship - because the team members were not frantically

fixing things most of the time, they spent a lot of time talking

to the other teams and providing tools and food where needed.

-

Best and Most

Complete Costing Report - this reinforced the team's original

emphasis on the static aspects of the competition.

The team

placed 4th overall in the 1987 competition. This was a

remarkable achievement for an first-time entry, especially so when

you consider that it has yet to be beaten by any Canadian team

since then! 1987 was also the year when the annual award-winning

tradition of the University Waterloo Formula SAE Team began.

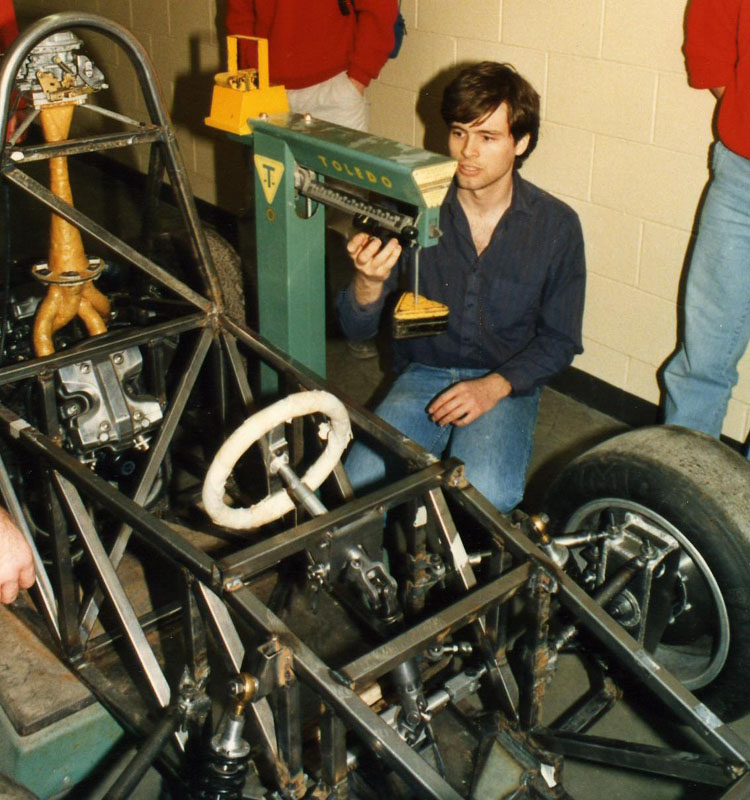

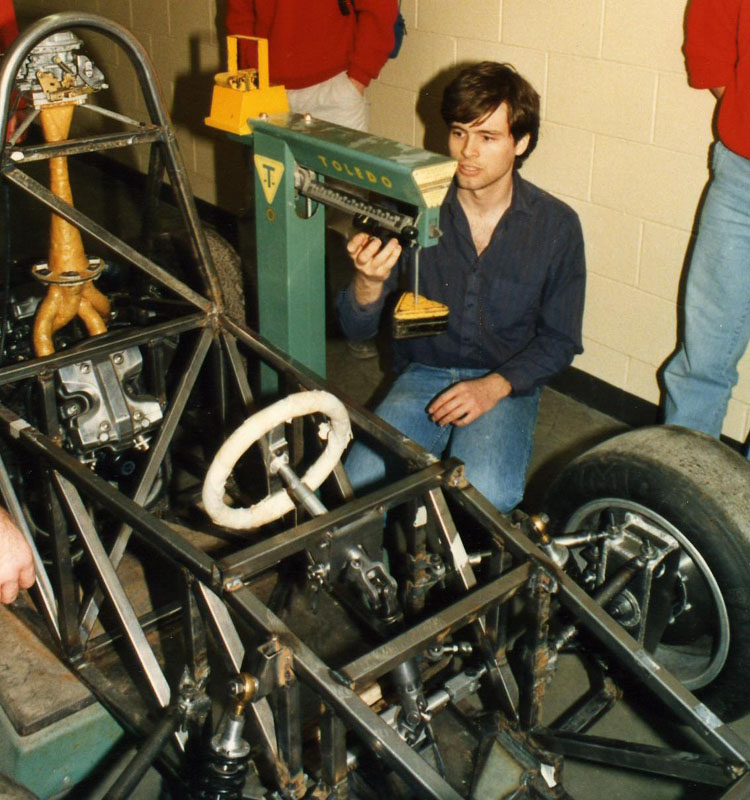

Weighing the chassis

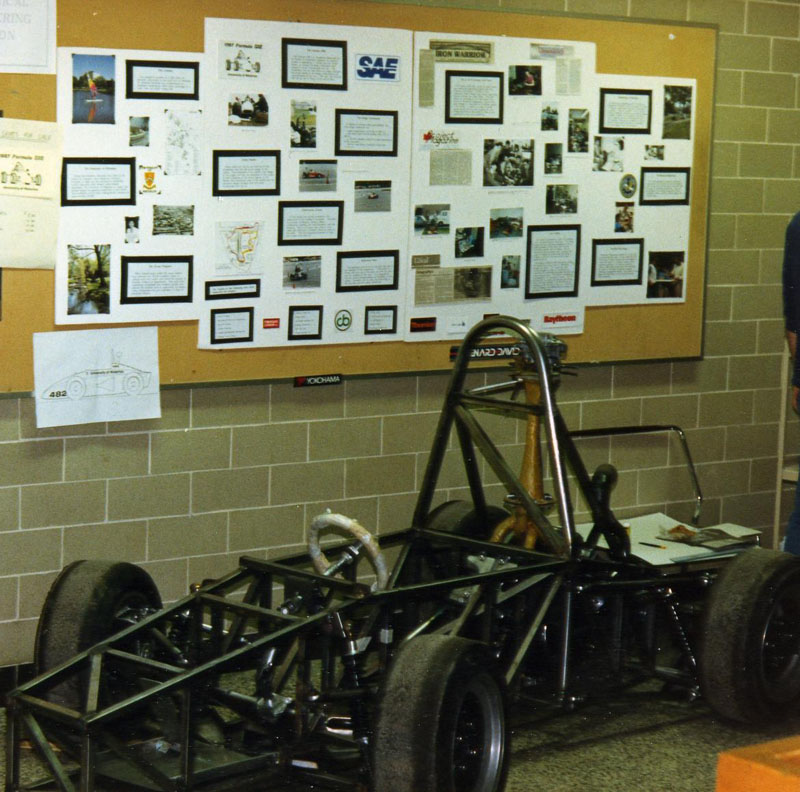

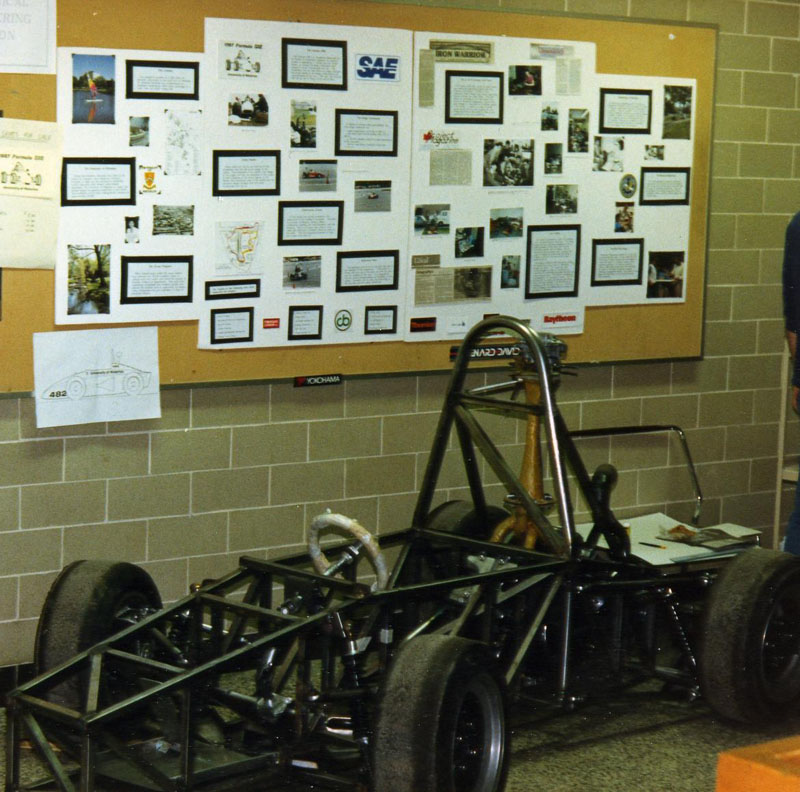

The

car on display

Text

and pictures courtesy of Evan Jones, a member of the 1987 Team.

Edited

by Peter Yang and Will Chan