The proposed fire detection system is made up of the four sensors detailed in the

Proposed Solution section. These sensors are to be mounted on top of the PC-BOTS

and aimed in the forward path direction of the robots. The minimum viewing angle

out of all of the sensors, with the exception of the smoke alarm is 90⁰. If

these sensors are placed adjacent to one another, a problem arises with the

field of view of each of the sensors not lining up completely. This may cause

one sensor to trigger a positive reading before others and may cause a missed

positive due to failed redundancy. This is illustrated in the following figure.

Since the sensors cannot distinguish which region the measurement was taken,

with the exception of the night vision web camera, the robot will have to stop

and pivot in one location in order to verify that any readings in the unreliable

region can be confirmed to a certain degree by the remaining sensors. This will

reduce the efficiency of the fire search method but is only likely to occur when

there is either a large presence of false alarm stimuli in the same area or a

fire. An alternative is to stack the sensors vertically, however, there arises a

need for a complex housing to be custom built to prevent damage to the sensor

components when mounting the sensors on top of one another. Furthermore, this

only shifts the same problem to the vertical scale, as the vertical field of

view would no longer line up. For this reason, the sensors are to be mounted

adjacently and the robot is designed to pivot in the presence of only a single

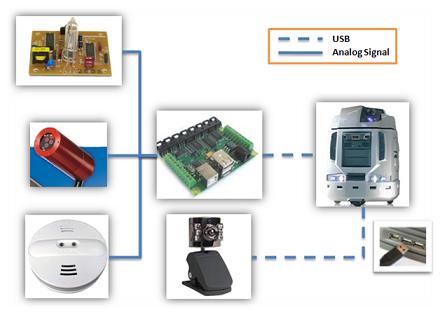

positive fire signal. The integration procedure of these sensors into the

overall robot system is illustrated in the following figure. The analog outputs

of the UVTron and NetSafety Triple IR are directly connected to the expansion

I/O card of the PC-BOT in order to convert the signals to computer readable

digital signals. The smoke alarm is also connected to the I/O card after

reconfiguring the alarm circuit to send the alarm signal to the I/O card rather

than the speaker. The webcam is directly connected to the PC-BOT through a USB

2.0 connection.

All of these sensors, with the exclusion of the webcam, require basic high level

drivers to be built using Player API. Through these drivers the sensor

measurements can be read by the program running on the Player environment which

is controlling each robot. Along with drivers, an entire vision system needs to

be written using open source OpenCV vision libraries to provide added redundancy

in fire and smoke detection readings. Several methods exist for the detection of

fire through live video capture. A few of these methods are explained in [3],

where emphasis is placed on the wavelet domain analysis of moving object

contours being the most effective technique of identifying fires with a minimum

number of false alarms. Wavelets are high-pass filtered measurements of pixel

colours. In the wavelet domain, a high-pass filter of 10Hz enables random agents

such as fire to pass through due to its inherent flicker frequency. However, it

is also known that this frequency is not constant for all fires, but rather

changes for different fuel sources and environment conditions. This frequency is

not even consistent for a single fire, but rather acts extremely randomly. This

is why a Markov model is used to analyze the contours of fire-coloured pixels

that have already passed through the filtered wavelet domain. The random

flickering of the contours of fire are to be used to identify the fires through

video.

Based on the design objectives and constraints, the overall fire detection

system does indeed meet all of the requirements. In terms of accuracy and the

minimization of false alarms, four sensors are being used to build redundancy

checks to ensure that only fires set of alarms. Furthermore the inclusion of

high-end infrared detection technology and the latest vision algorithms makes

this system severely less prone to false alarms. The actual false alarm rate of

this system has yet to be determined. Lastly, the cost objective is also met as

the sensor system does not cost more than $4000. Since the fires are being

constrained to class A fires, the infrared sensor alone is more than capable of

detecting these types of fires. Furthermore, the use of a vision system for

added smoke detection redundancy improves upon the ability of the fire detection

system to pick up desk fires and garbage bin fires, as part of the design

constraints. Lastly, the addition of an UV sensor allows for the detection of

erroneous false alarm stimuli such as welding, sunlight, etc.