Welcome to our project

This project is our Fourth Year Design

Project, which is part of the Mechatronics Engineering program at the

University of Waterloo. This site is pretty bare-bones at the moment,

but we'll be updating the photo gallery as our project progresses. Be sure to check it out!

what is it?

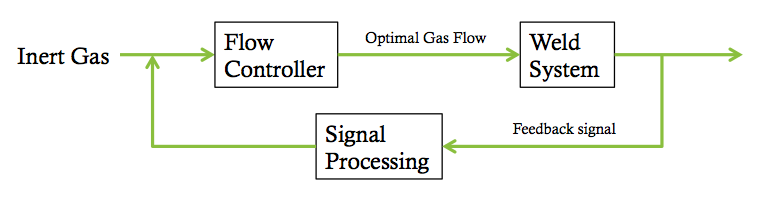

Our design is a MIG welding gas flow controller. MIG (Mixed Inert Gas) welding is a particular type of welding. When metal is heated up and melted, it becomes susceptible to oxidation. The oxygen in the air nearby gets into the liquid metal and creates large, unwanted pores which compromise the strength and integrity of the weld. To prevent this from happening, a cone of inert gas is blasted out to shield the melted metal from the oxygen in the air. Typically, in industrial settings, the amount of gas used is often much more than is needed. The gas valve is often just fully opened to play it safe, and this ends up wasting a lot of gas. Our project aims to tackle this problem.

Our gas flow controller is being designed to dynamically alter the

gas flow rate as needed, to reduce the amount of gas that is wasted in

the welding process. It is meant to be modular and usable with any MIG

welder.

how does it work?

Based on lab experiments that we have conducted, we determined

that when oxidation occurs, we can reliably detect the porous spattering

by analyzing the frequency spectrum of the electrical current outputted

by the welder. When oxidation occurs, it introduces high frequency

oscillations in the current signal.

A current-measuring sensor is attached around the welding power supply cable, and the sensor gives this information to our microcontroller. This microcontroller is programmed to perform Fourier transforms of this data on the fly, which allows us to constantly monitor the frequency content of the electrical current. When high frequency oscillations are detected, our algorithm decides how much the gas flow needs to be adjusted. This same microcontroller then controls a motor-actuated valve which is attached in-line with the gas source, adjusting the gas flow up and down as needed.