Problems identified in existing walker are

* Mechanical braking levers require too much force from the user

* Brake on existing model is ineffective

* Replacing components - interchangeability

Our Proposed design

Problems identified in existing walker are

* Mechanical braking levers require too much force from the user

* Brake on existing model is ineffective

* Replacing components - interchangeability

Our Proposed design

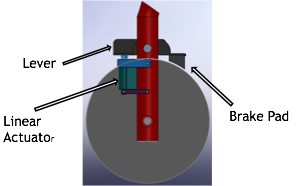

In the proposed design, the electrical force from a motor would be converted into mechanical force in the handle and to a frictional force in the brake, this design would use a linear actuator directly on the brake which would result in decreased energy loss in the system and a much simpler build.

From the existing system the only additional components are the linear actuators and the bracket that holds it to the side of the wheel. Principally as the linear actuator extends it causes the lever holding the brake to pivot and engage the wheel causing it to slow down. This solution satisfies all the constraints and criteria mentioned earlier. It is a much more simple design and is very easy to implement. It also allows for increased flexibility as it is extremely easy to repair or replace any parts.

The final design of the proposed solution focused on three main elements:

•Mechanical Levers

From the mechanical design perspective, the mechanical braking levers on the current walkers require too much input force from the user. These braking levers are not adjustable and are uncomfortable to hold over long periods of time. The mechanical design will focus on eliminating the handles from the final walker and replacing them with linear actuators controlling the brakes at the wheel itself.

•Brake pad

The current walker that is being used to build upon does not have a robust brake pad. This pad is simply a point of contact on the wheel itself. Performing simple stress tests show that even when the brake is fully engaged the wheel and by extent the walker is free to move. Though there is very little engineering analysis to construct a brake pad that covers a larger surface area it is an important consideration in terms of figuring out available braking forces/torque.

•Interchangeable Parts

One of the major drawbacks to most assistive walkers is that the components of the braking system itself are not easily interchangeable. Although these components are very simple and unlikely to fail given most reasonable circumstances and usage it should set to reason that if it were to fail due to the handle being stuck or wire snapping that any repair should be a minor thing. However visually inspecting the walker shows no sign of a quick repair design build. Therefore, in this mechanical design although it simply consists of a linear actuator, a bracket, a lever, and the contact pad these components should be built in such a way that makes it easy for anyone with a simple toolset and proper replacement components to fix it.