Proposed Solution

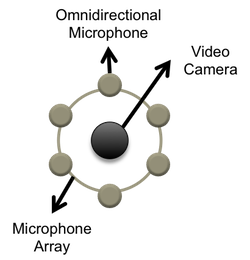

The solution that has been proposed by Group 10 is to use a single circular microphone array for source localization and beamforming. The design also incorporates a single camera in the center, which will pivot towards a person who is talking, based on the information from source localization. The advantage of this technique is that sound is collected from a stationary array, which can pick up the direction of a sound source in a fraction of a second. This same array can be used for noise cancellation spatially, which will allow for an audible decrease in background noise.

Functional Overview

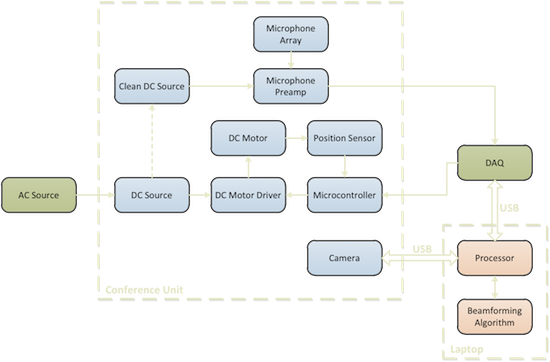

There are three main components to the system being implemented. These are the camera rotation system, the microphone circuits and the data acquisition and signal processing system. The flow of the system is as follows: a sound is produced and picked up by each microphone. The signal from the microphones is amplified by the preamplifiers. This signal is then captured by the DAQ. This data is then processed to determine the direction that the sound arrived from using source localization. This information is then used by the beamformer to cancel noise. Simultaneously the position is sent to the camera drive system, which will turn the camera towards the sound. The picture below shows a visual representation of this interaction, while the details of these components are outlined in the sections below.

Camera Rotation System

This system is designed as a separate module, which receives a desired direction signal from the DAQ and source localization algorithm and rotates the camera in the speaker's direction. The components of this system include a camera, DC motor, gearing system, H-bridge driver, and a microcontroller.

Camera

The selected camera is the Microsoft LifeCam Studio, which features a high definition 1080p sensor with autofocus to 4 inches. The camera interfaces using USB.

DC Motor

The selected DC motor is required to meet the rotational speed and torque requirements of the system – one rotation from rest in one second. The motor is also selected to be small in size and as quiet as possible.

Gearing System

In order to keep the system as quiet as possible, a pulley and timing belt system is chosen over a gearbox. A 6:1 reduction is used to achieve the required torque. A MXL series neoprene timing belt is used for silent operation.

H-Bridge Driver

The H-bridge driver is used to control the direction and speed of the DC motor using a PWM signal. The selected H-Bridge driver is required to meet the current and voltage requirements of the DC motor. L298N is a full-bridge driver with support for up to 4A and 48V, which is within the motor operating range.

Microcontroller

The microcontroller is required to receive an analog input signal from the DAQ, which indicates the camera direction. In addition the microcontroller will run a closed loop controller to position the camera in the correct direction. The microcontroller will track the camera position using an analog position sensor and drive the motor using a PWM signal to the H-bridge. The selected microcontroller is the low cost Texas Instruments MSP-430.

Top of PageMicrophone Circuits

When designing the microphone circuits it was important to take into account both the quality of the microphone and as well as the preamplifier. These components then had to be integrated, so that an output signal of sufficient amplitude could be output to the audio capture device.

Microphone

It was important to choose a microphone with an operating range that

encompasses the traditional wide-band audio frequency range used in

telephony. This range is 30 Hz - 7000 Hz. To ensure that we did not

have any audible noise from the microphones we also required a high

signal to noise ratio. The final requirement of this sensor is that the

frequency response was wide and flat, so that it would work well with

the source localization and beamforming algorithms. Ultimately, the

Panasonic WM-64PNT microphones were used.

It was important to choose a microphone with an operating range that

encompasses the traditional wide-band audio frequency range used in

telephony. This range is 30 Hz - 7000 Hz. To ensure that we did not

have any audible noise from the microphones we also required a high

signal to noise ratio. The final requirement of this sensor is that the

frequency response was wide and flat, so that it would work well with

the source localization and beamforming algorithms. Ultimately, the

Panasonic WM-64PNT microphones were used.

Preamplifier

To provide an appropriate level for the output signal, a preamplifier with a gain 200 times amplification was required. Also, similar to the microphones, the preamplifier circuit required an operating range that encompasses the wide-band telephony frequency range and needed a wide, flat frequency response. The final choice of preamplifier circuit was the National Semiconductor LM386.

Top of PageSource Localization

An important part of the solution is, knowing the location of the acoustic source (Speaker's locations). There are several algorithms involved that would aid in locating the origination of the sound waves. Direction of arrival (DOA) and Time Delay of Arrival (TDOA) of the sound waves could allow one to locate the speaker. Here, a pair of microphone is used to estimate the time delay of arrival between each successive microphone. Using simple geometry and the right time delay estimation the location of the speaker could be found. This time delay could be used to equalize the signals received by each of the microphones. Different combinations of the time delays with weighting function are used to match the signals with microphones. The best combination that matches yields the right time delay estimation. Once, time delay between successive microphones is found the location of the acoustic source could be found and source localization is successful.

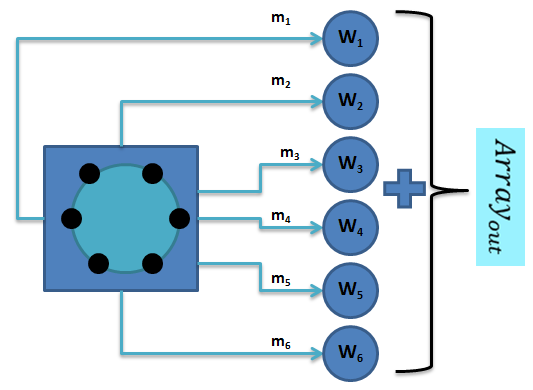

Beamforming

Beamforming gives one the ability to combine signals from more than one sensor. This could be done with any type of sensors. In our case the signal received by each of the microphone is formed of the speaker's speech and the noise in the environment. Beamforming allows us to post process and combine the signals from all the channels to help focus the microphone array in one direction, usually referred to as directive beamforming. This helps the setup in eliminating the background noise, which in turn will increase overall signal to noise ratio. Thus, by specifying the look direction once the source location is identified, each microphone could be weighted in a way that will cause the microphone array to look towards the speaker and reject most of the noise coming from any other direction.

References

- Omnidirectional Back Electret Condenser Microphone Cartridge WM-64PN [online]. Panasonic. 05 Dec. 2010. http://industrial.panasonic.com/www-data/pdf/ABA5000/ABA5000CE11.pdf