Most microfluidic chips developed for cell culture applications use a syringe pump to provide a source of pressure driven flow. However, syringe pumps lack the flexibility and the response time needed in multi-functional chips that require control over several fluid streams. An alternative to using pressure driven flow is electroosmotic flow (EOF) which is a compact method for pumping fluids in microchannels where flow rate and direction is controlled by manipulating applied voltages at the reservoirs. But EOF cannot be directly applied to living cells because the high electric field, joule heating and high shear stress associated with EOF negatively influences the cells.

These problems can be avoided by using EOF in the form of an electroosmotic pump (EO pump) which generates an induced pressure driven flow from EOF. EO pumps provide pulse free flow, almost instant flow control, and precise movement of minute volumes of fluid (µL-pL). The integration of internal pumps onto the chip also opens up the possibility of multi-fluid control without valves.

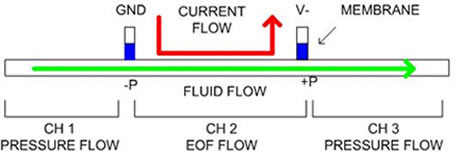

EO Pump Operating Principals:

With an EO pump (see figure below) an electric field is applied in a limited region generating EOF flow (channel 2). Membranes seperate the electrodes from the internal fluid channel allowing for electric current to pass but not the fluid. Becaue of continuity, an internal pressure is generated that pumps the fluid outside the EOF region, vacuum draws the fluid into the pump (channel 1) and a positive pressure drives the fluid out (channel 3). The fluid flow in channel 2 is actually a combination of EOF flow and back pressure flow. A cell chamber can be placed before or after the EO pump allowing for the use of EOF while isolating the cells from the electric field.

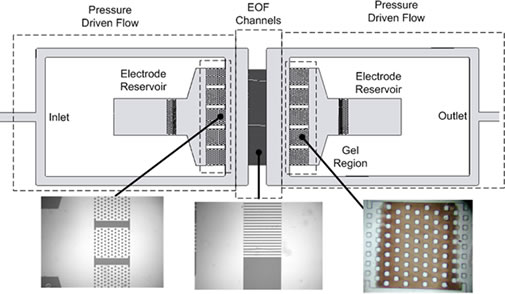

EO Pump Designed for Cell Culture:

Each EO pump consists of a region of 35 parallel channels (2.78µm H x 100µm W x 1 mm L) that carries the electric field (see figure below). A series of integrated gel salt bridges provide an electrical contact between the Pt electrodes in the reservoirs and the working fluid in the channels. The gel salt bridge minimizes negative electrolysis effects that reduce pump performance such as bubble formation and pH changes.

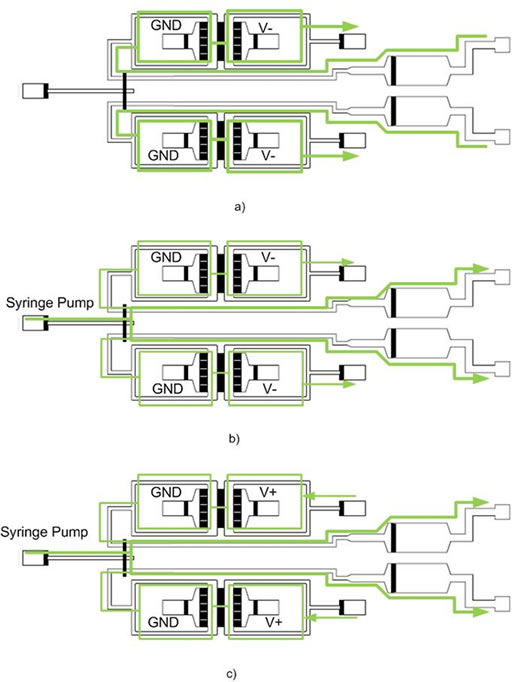

Cell Culture Chip:

A cell culture chip was designed with two EO pumps integrated on chip to demonstrate their potential. The chip can run in several configurations (see figure below):

1. EO pumps are used to draw the fluid from reservoirs 2 and 3 over the cells in the chamber (flow is from R2->R4, R3->R5). Placement of the pump downstream from the cells avoids passing the fluid through the pump first and then over the cells. As well, the electrode near the cell chamber is GND and the other a negative (-V), so the cells do not experience a high voltage.

2. Flow from a pressure driven source such as a syringe pump provides constant flow over the cells (R1->R4, R1->R5). The EO pumps operate in the same configuration as before and divert flow away from the chambers dynamically regulating flow to the cells from a syringe pump without the need for integrated valves.

3. The EO pumps operate in the opposite direction and dispense small amounts of fluid into the main stream such as drugs to the cells.

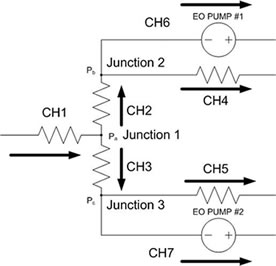

The flow network may be described by a 1D circuit model for the flow field. The conditions of using this model include that the flow is laminar and the Navier-Stokes equations become linear, which are valid for planar EO pumps.

.

.

Operational conditions of the EO pump cell culture chip for testing (Left) and 1D compact circuit model of the network used to design the microchannels and chip (Right). Completed chip in PDMS with dye filled microchannel for visualization of the network (Bottom).

The EO pumps have been tested and verified, currently experiments with cells are underway.

For more information on this project please refer to the following publication: