Microfluidic devices that incorporate heat transfer must be characterized by measuring in-channel temperatures during operation. Temperature measurements are usually accomplished visually by adding an indicator to the working fluid and imaging the area of interest. One of the most common methods uses a temperature dependent fluorescent dye such as Rhodamine B (RhB). However, Rhodamine B is incompatible with PDMS microchannels as it easily absorbs into the walls resulting in a steady increase in the overall fluorescent signal, which in turn, causes significant measurement errors.

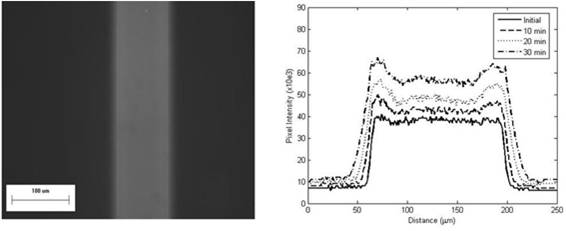

Image of a 100μM Rhodamine B filled PDMS microchannel after 30 minutes (left) and the corresponding fluorescent intensity profile at 10, 20 and 30 minutes (right). Absorption and adsorption is evident due to the detectable fluorescent signal extending beyond the channel walls. Over time the absorbed dye also increases the fluorescent signal.

Image of a 100μM Rhodamine B filled PDMS microchannel after 30 minutes (left) and the corresponding fluorescent intensity profile at 10, 20 and 30 minutes (right). Absorption and adsorption is evident due to the detectable fluorescent signal extending beyond the channel walls. Over time the absorbed dye also increases the fluorescent signal.

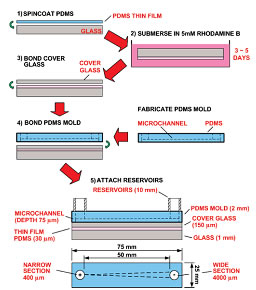

To resolve this issue we actually used the absorption to our advantage and developed a thin PDMS film saturated with RhB. The film consists of three parts: (1) a glass slide for a base (2) a thin 30Ám spincoated PDMS layer saturated with RhB and (3) a thin glass sheet cover that prevents RhB from leaching back into the fluid stream. The three layer package is then bonded to the PDMS microchannel mold that is to be tested. The fabrication procedure and calibration curve for the thin-film are shown below.

Fabrication procedure for the thin film and the test tapered channel chip (Left). Calibration curve for the thin film with the results published by Ross et. al. [1] (Right).

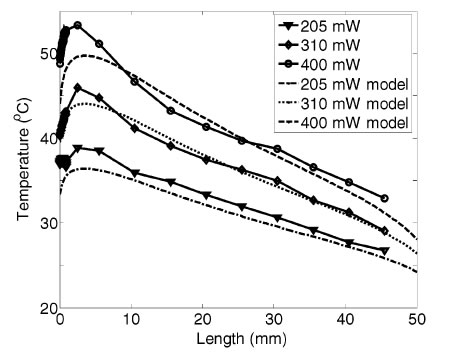

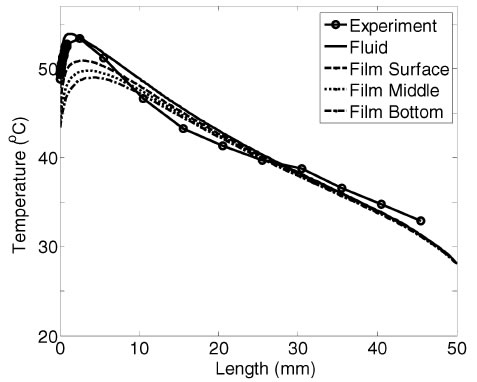

An advantage of using the thin film is that the temperature field can be measured in the plane of the film producing a 2D temperature map. To test its performance, the thin film was used to measure the non-uniform temperature field along a tapered microchannel under going joule heating. A comparison of the experimental and numerical results along the axis of the channel are shown below. Numerical simulation results of the temperature profile through the thickness of the film is also shown.

Experimental and numerical results of the temperature profile along the axis of the tapered channel for various applied input powers (Left). Results for temperature axial temperature profile at the top, middle, and bottom of the film with a comparison to experimental results (Right).

Experimental and numerical results of the temperature profile along the axis of the tapered channel for various applied input powers (Left). Results for temperature axial temperature profile at the top, middle, and bottom of the film with a comparison to experimental results (Right).

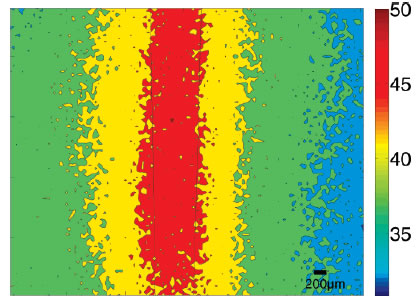

A temperature map at the hottest point along the channel axis demonstrates the possibility of obtaining whole-chip measurements.

For more information on this project please refer to the following publication:

[1] Ross, D.; Gaitan, M.; Locascio, L. E. Anal. Chem. 2001, 73, 4117-4123.